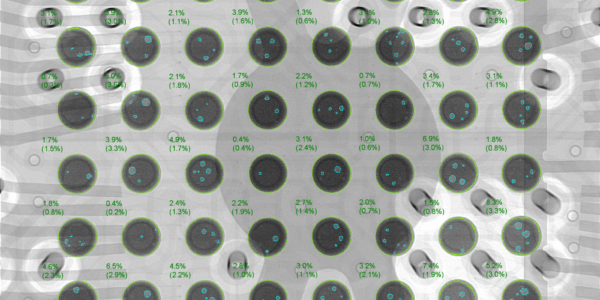

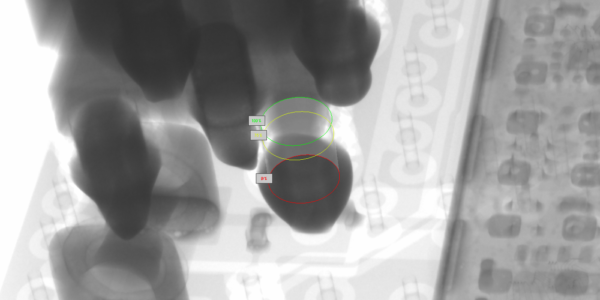

X-ray inspections are one of the best solutions for not only finding and analyzing defects within your assembly in a non-destructive manner, but to have peace of mind that your application is sound from errors earlier in the manufacturing process.

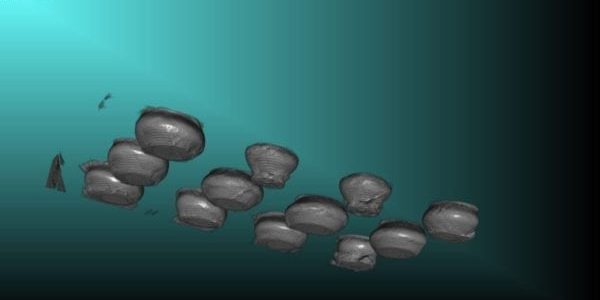

Offering real-time 2D and 3D digital x-ray inspection services for PCB components, assemblies, and other electronic devices.

Providing this service along with a trained and certified process engineer on-site at our faculty with your resources. We also provide remote inspections using our real-time conferencing system for an interactive experience.

X-Ray Inspection Overview

X-ray inspections offer electronic manufacturers and assemblers a way to inspect defects within their products. Easily in a non-destructive manner, in locations that are hidden or impossible to inspect optically.

With this being said x-ray inspections become an important method of validating production processes earlier on before a later stage in the manufacturing timeline. Which can lead to increased cost and loss of time and resources.

Common X-ray Inspection Defects

There are a lot common defects and faults that can come into account during the manufacturing and assembly process of electronic devices.

- BGA Voiding

- Wicking of BGA Solder Balls

- BGA Pop Corning / Cracking

- Missing Solder Balls

- Incomplete Reflow

- Misalignment of BGA Package

- Solder Shorts/Bridges

- Flip Chip Open Circuit

- Joint Voiding

- Through Hole Incomplete Fill

- Cracks & Breaks in Tracks, Joints, & Components

X-Ray Inspection Service Request

Please complete the form below to request an x-ray inspection. Give us a call at 1.800.344.4685 to speak with one of our specialists for more information about our capabilities and reoccurring pricing.